Lean Six Sigma Curriculum for Raleigh High School Students of North Carolina

Contact Us

Lean Six Sigma can be used by businesses and companies to improve their systems and operations so they can remain competitive and increase their production. Now, this was not well-known at the time, in the late 80s, but practitioners obtain additional benefits by just knowing how the methodology works. Those who are familiar with the subject know that LSS can be used to empower people in all stages of life and assist them in gaining more competitive aspects. Lean Six Sigma Curriculum for Raleigh High School Students of North Carolina is a hard-working company that can help you understand everything about Sigma:

- LSS is essential for all students in high school, college, and business.

- LSS training and certification is required in order to allow them to access the methodology.

- Assist them with learning how to use it—and with “them” we mean anyone interested in the methodology.

- Help companies improve their processes, create programs to teach employees how Sigma works, and even establish a new course in a school for all individuals.

We understand that many questions will arise as the method’s structures and principles are designed for manufacturing. It is easy to see how other industries can benefit.

You can minimize the number of steps required and maximize your results if you focus on creating and adapting them to meet your specific needs.

This approach is very popular at universities and colleges today for the reasons mentioned above. This allows people to concentrate on their goals, not just the business strategy or how the method can be used for a business or commercial entity.

Companies and businesses might allow employees to become certified. However, only the person who has been trained will be able to implement the method. This makes them a valuable asset no matter where they go.

If companies don’t have the knowledge and skills to use LSS principles and structures effectively, they won’t be able innovate, grow, or improve their businesses. This is only possible with well-trained practitioners.

It can help you gain career benefits and increase your chances of success as a student, professional, or college student.

These are the top three benefits of implementing Sigma within your company, if you’re interested in it:

- Lowers your costs.

- Customers are happier.

- Reduced lead times.

But if you are a person or future practitioner, you may want to keep these two benefits for individuals in mind:

- This opens up new opportunities for professionals and students to find better jobs and careers.

- It increases efficiency and encourages trainees to be more diligent.

Our training can be used by high school students to increase their chances of getting into college or finding better jobs. The training can be used by college students to gain experience and get ahead of their peers as well.

How It All Started with Lean 6 Sigma

We must look back to the past in order to understand the methodology. LSS could be described as a combination of Six Sigma and Lean, which it is. However, there is more to the past than what we know about each. Understanding the whole concept will be easier if you start with the principles and basics of each methodology.

Toyota created Lean manufacturing in the late 1940s to decrease non-value-adding activities. This is the most important point to remember, as Lean manufacturing incorporates many of the principles regarding reducing waste to LSS.

The core values of Lean management include:

- Customer satisfaction is our main focus.

- Reduce waste in your workflow.

- Continuous improvement of processes, cycles, and every step of the industry and system.

- To foster excellence, employees must participate in organizational change.

Although Lean may appear simple based on the above values, it is a complex methodology that has seen significant progress in reducing waste and improving productivity. However, people need to be able to adapt the structure and the methodology.

Six Sigma, a process improvement technique, dates back to the 1980s. Motorola used Six Sigma in order to reduce variability and identify and minimize defects.

Six Sigma’s core values include:

- Concentrate on quantifiable financial results.

- Your success depends on your leadership and the support of your management.

- Data-based decisions are made based on statistical data, not assumptions.

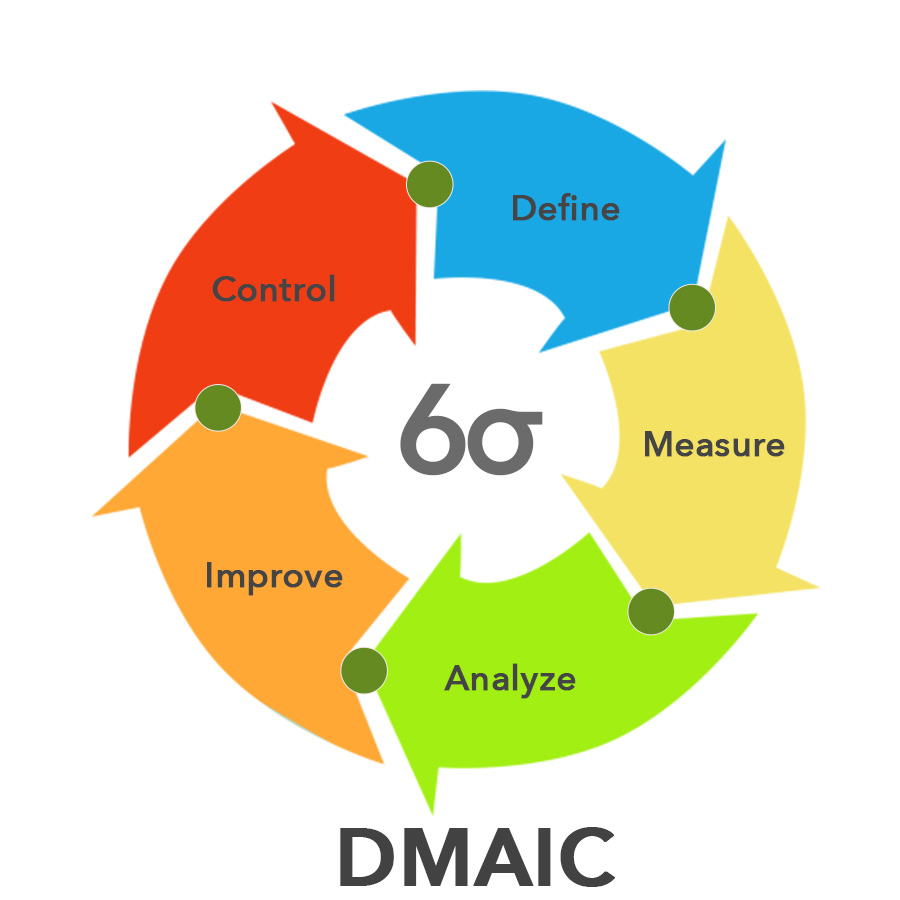

The DMAIC structure is used to implement this strategy. It stands for Define, Measure, Analyze, Improve, Control. This method helps you identify and solve problems and it’s possible to make a change in your company and get the best out of each process.

Six Sigma’s principles, along with the whole idea of Lean, and all its phases, are combined to create all of Lean Six Sigma’s core values and phases. Additional phases can be added based on the company’s goals and needs. So, all the gaps between Lean and 6 Sigma will be filled by LSS and the additions.

The DMAIC Structure Allows for Change

This structure adapted from 6 Sigma alone helps achieve all the results related to reducing variations and working with the whole methodology when translated into LSS alone:

- Define your problem from both a business and customer perspective. These questions or equivalents are necessary to determine the problem.

- Are you able to meet quality standards?

- What problem are stakeholders trying to solve?

- Can the problem be viewed from both a business and broader perspective?

- Assess your current performance and answer this question: Does it meet the quality requirements set in the previous phases and what do customers require?

- Analyze all the data to determine the root cause of any problem that was not found in the initial phase. To pinpoint the root cause, you can use lean analytical tools such as Value Stream Mapping and Just-In-Time.

- Improve all the processes to resolve the problem once the root cause is identified.

- Manage your solutions and processes. This phase will allow you to establish acceptable performance criteria, and make a plan for correcting any deviations.

These phases and structures show that this method is not restricted to businesses and manufacturing firms. Students and business professionals can experience growth and improvement through DMAIC if they know how to adapt it accordingly.

Although it is important to adjust and adapt, the idea of identifying the problem and then making sure that all data is accessible leads to solutions to ensure continued growth.

Lean Six Sigma: Benefits for Companies & Trainees

This part will help you understand the two types of benefits you can get from this method. It is based on what your company needs or what an individual looking to improve their current knowledge.

Organizational benefits include:

- Simpler processes. This will help you find inefficiencies and eliminate waste while allowing you to manage your workflow much more easily.

- Increased predictability. Simplify your workflow.

- Higher profits and lower costs. A simplified delivery process will improve delivery speed and quality. This will naturally increase your revenue potential.

- Continuous growth. This goal is LSS. It is to ensure that the industry does not fall behind and that business moves forward.

Personal Benefits:

- Analytical thinking. Lean and Six Sigma can simplify complex problems.

- Efficiency. People can analyze their performance and identify root causes.

- Six Sigma project managers need to communicate with all levels of the organization, from strategy to operations. This will enable people to improve their project management skills, understand the business, and even choose to work in other areas.

- Career advantages. Individuals, businesses, and industries view LSS as an essential addition to their operations.

- Anyone can learn to manage their time, lead and collaborate with others, and make informed decisions.

LSS allows students and trainees to access tools that can help them in other areas of life, such as education and work. Don’t think of LSS as a way to get work at a particular company, but instead, focus on how you can use it for personal growth.

Lean Six Sigma Curriculum Pros of Raleigh offers certifications and training for all three phases of your life, high school, college, and work. You don’t need to be a worker to reap the benefits.

Let’s say you have completed the yellow belt training which focuses on LSS terminology. You will become more organized and confident in what you can do. A green belt will give you more confidence when managing large-scale projects for yourself or other companies.

No matter which belt you choose, we offer certification and training in both yellow and green belts so that you can begin this method and scale up later.

Leadership Excellence and Innovation Consulting for All

Being a leader is a key skill that can open up many doors and we are confident about our service so you are able to work around your leadership excellence and ensure you develop and improve this skill.

We are passionate about leadership training and supporting workers or groups who want to improve this skill.

We also offer workshops and innovation consulting to individuals and companies who are looking for growth, a better mind, and staying competitive.

Our team has so much to offer, we encourage you contact us to learn more about our solutions. We will gladly provide all relevant information if you let us know for whom it is.