Raleigh Residents - Learn Lean Six Sigma’s History Here

Contact Us

Many people think that Lean Six Sigma History is easy to understand and absorb. It is difficult to know every detail of the history of Lean Six Sigma because there are many methodologies, more historical periods, and more studies and analyses. However, it is important to understand how and why something was created in order to properly learn and apply it. Every student should be able to comprehend LSS right from the beginning. This is why Lean Six Sigma Curriculum Birmingham High School Students of Alabama offers LSS education.

LSS is a process that reduces waste, improves processes, and achieves continuous improvement. It also works towards increasing revenue and reducing costs. This is all about how companies need to work around their processes and focus on getting better results from less.

This methodology will focus on how they can identify and manage issues and problems, and then implement solutions to stop them from happening again.

Is this where the idea for LSS originated? It’s history!

LSS was established to solve the problem facing American companies: Japanese companies enjoyed dominance in production and markets during the 1980s, thanks to their superior products. They also ensured that waste and costs were decreased.

Japan used many different methods. Kaizen is the most popular. This system focuses on customer satisfaction and waste reduction.

They were able to achieve exceptional results in manufacturing thanks to this approach. This led to an increase in the demand for LSS (or a methodology that would allow USA companies to compete).

How do Japanese Methodologies Influence LSS

It is important to know how other methodologies influenced the idea for Sigma. Also, how people came up with the conclusion that LSS was overall a good idea. There are always many principles and ideas that influence the creation of a methodology.

There are some methods you should keep in mind when trying to understand LSS:

- Kanban method for workflow management

- Value stream mapping for optimizing process delivery.

- This five-step process will optimize your work and increase efficiency.

Two main methods are required for LSS to occur and be created. These are Six Sigma and Lean. Both methodologies have a focus, but are different, on improving the lives of people.

Six Sigma, Lean, and LSS: How They Aided

Toyota developed Lean in the late 1940s as a way to reduce non-value-adding activities, improve performance and take care of all types and forms of waste.

Lean management’s core values include:

- Your top priorities are customer service and satisfaction.

- All waste from work must be minimized.

- Continuous improvement and keeping your clients in view.

Toyota Production Systems (TPS), is where Lean was first established. It is also the place where Lean was first used, thanks to Japanese Taiichi Okno.

According to some data, Lean also draws on Henry Ford’s innovations and Business Process Redesign.

Although the methodology is structured in a certain way, it can be modified to suit your specific needs and goals.

- Lean begins with determining the customer’s added value.

- It is important to map the value stream (processes and cycles that support it)

- Recognize and improve waste flow. To expose waste, data is collected and shared.

- Talk about how to reduce waste and keep the customer in mind when creating products, projects, or any other ideas.

- Employees need to identify the areas that they can improve, and then work together to fix it.

What is 6 Sigma?

Motorola invented the method. General Electric used it successfully at the time. It was intended–and still is–to reduce variability in manufacturing processes many years later.

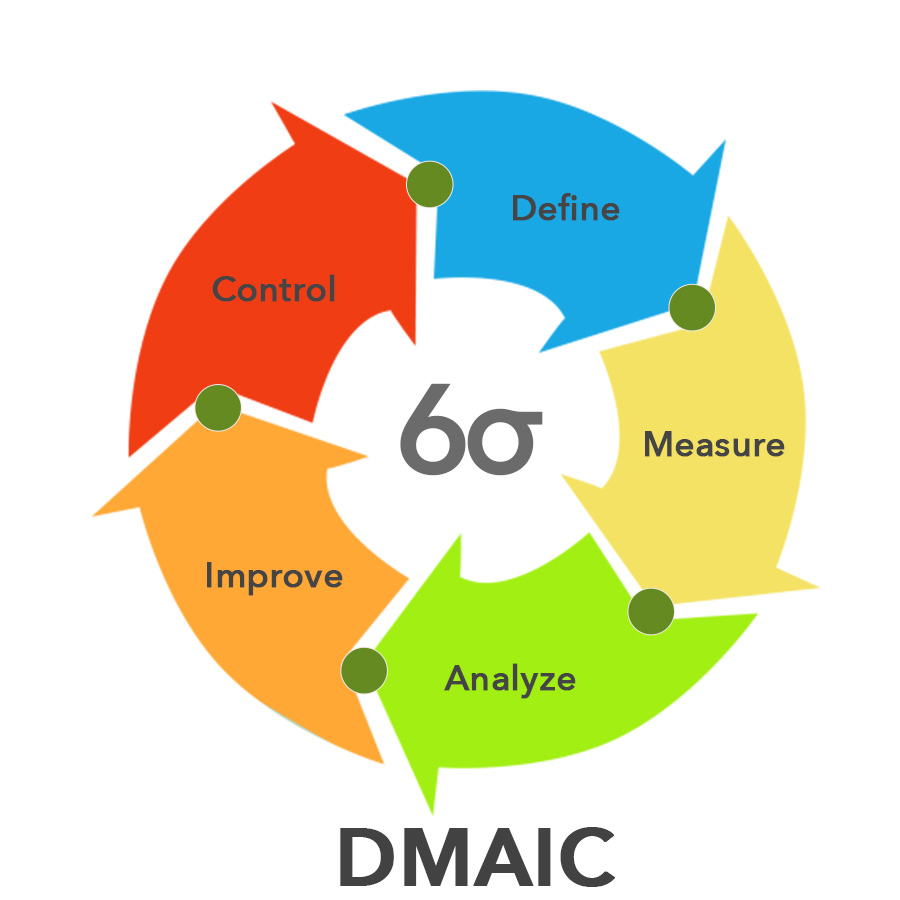

It is based upon the DMAIC framework which allows processes and wastes to be identified and measured. These are then improved and tracked to ensure continuous improvement.

Six Sigma provides managers with the tools and targets to help them create a structured improvement plan. It ensures that they are identifying the root causes of problems and then finding solutions.

Where is LSS left in this?

Lean Six Sigma was established in the USA. Its origins lie in the fact that Six Sigma was combined with Lean, but it adds more value to fill in the gaps. In the late 80s, American companies were able to compete with Japanese products.

It has been used extensively in many industries since then. It’s a useful addition to any curriculum, as trainees can also benefit from being sought after by organizations who require its implementation.

If you are interested in adding Lean Six Sigma Curriculum Pros to your curriculum, to increase its value, and to learn a great method, contact us.